-

Vidrio fundido en tanques de acero (465)

-

los tanques de acero inoxidables (434)

-

La fusión enlazó los tanques de epoxy (469)

-

Tanques de acero galvanizado (321)

-

Tejados de aluminio de la bóveda (1257)

-

Tanques de almacenamiento de aguas residuales (226)

-

tanques de acero soldados (457)

-

Recipientes del reactor (295)

-

Digestor anaerobio (201)

-

Los tanques de agua industriales (349)

-

Tanques de acero revestidos de vidrio (180)

-

Los tanques de acero empernados (270)

-

El tanque de almacenamiento del barro (115)

-

El tanque de almacenamiento del biogás (173)

-

Tanques de almacenamiento de lixiviación (133)

-

Tanques de almacenamiento de agua agrícola (179)

-

Tanque de agua de fuego (166)

-

Silos de almacenamiento de cereales (146)

-

Proyectos de biogás (381)

-

Proyectos del tratamiento de aguas residuales (270)

-

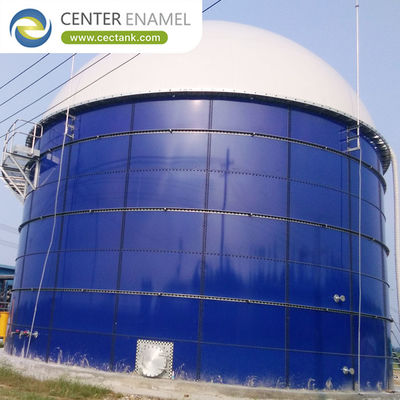

Techo de doble membrana (223)

Contenedor de biogás de doble membrana para una planta física de tratamiento de aguas residuales: utilizado para gestionar el biogás generado por procesos anaeróbicos de lodo asociados.

| Lugar de origen: | Porcelana |

| Nombre de la marca: | Center Enamel |

| Certificación: | ISO 9001:2008 , AWWA D103 , OSHA , BSCI |

| Número de modelo: | Techos de membrana individual y doble |

| Cantidad de orden mínima: | 1+ |

| Precio: | 0~99999 |

| Detalles de empaquetado: | Paquete de madera (personalizado) |

| Tiempo de entrega: | 45 días+ |

| Condiciones de pago: | T/T, LC/C |

|

Información detallada |

|||

Descripción del producto

Contenedor de biogás de doble membrana para una planta física de tratamiento de aguas residuales: utilizado para gestionar el biogás generado por procesos anaeróbicos de lodo asociados.

A. NoInstalación física de tratamiento de aguas residualesEl proceso de separación se realiza principalmente mediante técnicas de separación física (como la filtración, sedimentación y filtración) para eliminar sólidos y otras partículas.Estas plantas generan invariablemente un volumen significativo deLodoSi este lodo se estabiliza mediante digestión anaeróbica (AD), el método más común produce un valioso coproducto energético, rico en metano.Biogás, es creado.Contenedor de biogás de doble membranaEl desarrollo de las tecnologías de la información es un componente crítico de este sistema integrado.utilizado para la gestión de biogás generado por procesos de lodo anaeróbicos asociados, garantizando que la energía recuperada se capture y utilice de manera eficiente para compensar los costes operativos de la planta.

El...Contenedor de biogás de doble membranaEs la tecnología óptima para esta aplicación y proporciona una contención flexible y a baja presión para el gas recuperado.Instalado como techo flexible integrado en el digestor de lodos o como un compactoEste sistema garantiza la captura de cada metro cúbico de gas, la gestión de las fluctuaciones de presión de forma segura y unaSe mantiene un suministro continuo para la utilización de energía aguas abajo, convirtiendo un coste necesario de gestión de residuos (manejo de lodos) en una fuente de energía renovable.

Shijiazhuang Zhengzhong Technology Co., Ltd. (Enamel del centro), líder mundial en soluciones de contención avanzadas, especializado en la ingeniería de sistemas de almacenamiento de alto rendimiento.Contenedores de biogás de doble membranason contenedores de gas de última generación diseñados para integrarse perfectamente en la infraestructura de una planta de tratamiento de aguas residuales, ofreciendo una contención superior, regulación de la presión,y durabilidad a largo plazo.

Ventajas del producto para la gestión del biogás del proceso de lodo

Los contenedores de biogás de doble membrana de Center Enamel® están meticulosamente diseñados para manejar la salida de gas típica de la digestión continua de lodos.maximizar la eficiencia y la seguridad de la recuperación de metano para su reutilización en las plantas.

Gestión fiable del amortiguador de gas y de la presión

Los procesos de digestión de lodos producen a menudo biogás con variabilidad natural debido a los horarios de alimentación y las fluctuaciones de temperatura.reserva de gas flexible y dinámicacapacidad que puede expandirse y contraerse dinámicamente aadaptarse a las fluctuaciones de volumenEn la actualidad, la producción de biogás se centra en la producción de biogás.regulación de la baja presiónEsta estabilidad es fundamental para maximizar la compensación de energía interna de la planta de tratamiento.

Control de las emisiones fugitivas y de los olores

El sistema actúa como un factor crucialsello herméticosobre el digestor, que es primordial para ambosEficiencia máxima de captura de gasyControl de las emisiones fugitivasAdemás, el diseño sellado reduce significativamente la emisión de metano.emisiones de oloresLos sistemas de gestión de residuos y de residuos de residuos de residuos están asociados con la digestión de los lodos, garantizando un mejor rendimiento ambiental y el cumplimiento de la normativa local.

Apoyo para techos de cúpula de aluminio

Where maximum structural integrity and corrosion resistance are required for the digester tanks—especially critical in environments dealing with corrosive sludge and gas—the Double Membrane Holder can be installed on or adjacent to a tank protected by anTecho de cúpula de aluminioMientras que el sistema de membrana proporciona la envoltura flexible y hermética esencial, la cúpula de aluminio ofrece superiorprotección contra la corrosión a largo plazoy soporte estructural para toda la estructura del tanque de digestión, mejorando la durabilidad general del sistema.

Ventajas para la empresa

La posición de Center Enamel como proveedor global de primer nivel se basa en nuestra profunda experiencia técnica y compromiso con la calidad.Nuestra empresa posee décadas de historia probada en soluciones de contención de alto rendimientoNuestras capacidades de producción avanzadas están respaldadas pormás de 20 patentes en tecnología de esmaltey un equipo de investigación y desarrollo dedicado a la innovación.

Nuestra dedicación a la calidad se demuestra a través de nuestraEstricto cumplimiento de las normas internacionalesNuestros productos y procesos se ajustan a los estándares internacionales más exigentes, incluidos los estándares de gestión de la calidad, seguridad del agua potable y salud en el trabajo.Estas certificaciones proporcionan unagarantía independiente y verificable de calidad, seguridad y conformidadEl objetivo de la Comisión es garantizar que las empresas tengan un nivel de calidad de vida adecuado, con las regulaciones más estrictas, lo que es fundamental para el éxito de la operación en los mercados internacionales.Trayectoria mundial comprobadaEl éxito de los proyectos en más de 100 países, nos convierte en un socio confiable y experto para cualquier proyecto de tratamiento de aguas residuales municipales o industriales.

Áreas de aplicación del producto

Los contenedores de biogás de doble membrana de Center Enamel son componentes esenciales en varios sectores que utilizan tecnología de digestión anaeróbica:

Instalación física de tratamiento de aguas residuales:Se utiliza para gestionar el biogás generado por los procesos de lodo anaeróbicos asociados.

Instalación municipal de tratamiento de aguas residuales:Almacena el biogás producido por la digestión de lodos de aguas residuales para su reutilización energética.

Instalaciones industriales de biogás:Ofrece almacenamiento flexible de gran volumen para una producción de energía industrial eficiente.

Instalación de tratamiento de aguas residuales:Solución general para almacenar y amortiguar los volúmenes de gas del digestor recogidos.

Alcance global y excelencia comprobada: casos de proyectos

Nuestra amplia cartera de proyectos de contención exitosos muestra nuestra capacidad para diseñar soluciones robustas, selladas y duraderas.Los siguientes casos no ficticios demuestran nuestro alcance global y excelencia técnica:

Proyecto de tratamiento de residuos alimentarios de Beijing Fengtai:Hemos proporcionado3 tanquespara una instalación de tratamiento de residuos alimentarios en Beijing, destacando nuestro papel en soluciones sostenibles de transformación de residuos en energía cruciales para la producción de biogás.

Proyecto de tratamiento de residuos alimentarios de Guizhou Tongren:Hemos proporcionado2 tanquespara una instalación de tratamiento de residuos de alimentos en Guizhou, China, mostrando nuestro compromiso con la gestión eficiente de residuos orgánicos.

Grupo Muyuan Jiangsu Lianyungang Proyecto de aguas residuales de ganado:Para un importante cliente agrícola, suministramos7 tanquespara un proyecto de aguas residuales de ganado, demostrando nuestra experiencia en contención agrícola sellada de gran volumen crítica para la gestión del biogás.

Conclusión

Para unaInstalación física de tratamiento de aguas residuales, el contenedor de biogás de doble membrana es la solución óptima para recuperar energía de los residuos.utilizado para la gestión de biogás generado por procesos de lodo anaeróbicos asociados, garantiza la utilización segura y continua del combustible rico en metano,permitir que la planta reduzca al mínimo los costes operativos y mejore significativamente su balance energético general y su huella ambiental.